Scorpion Lift solution that rises above space constraints

“A lift solution that rises above space constraints.”

Often, a project requires the power of a crane, but the limited space pervasive to nuclear utilities makes using one costly and time-consuming preparations — if not completely impossible. To tackle this problem, PSC's engineers leveraged the law of physics and their knowledge to design an innovative solution: the patent-pending Scorpion System. The Scorpion's frame uses friction to support the crane on a single wall within a building or on an exterior structure to virtually eliminate the typical ground-level footprint required for a crane. A compressive load applied to both sides of the wall maintains positive engagement at all times.

The Scorpion System provides several advantages over traditional cranes: rapid assembly without time- consuming preparations, improved load handling efficiency, optimized load control and superior lift-to-weight ratios.

Time & Cost Savings

The Scorpion System shortens the project schedule and saves money by:

- Eliminating the need for a pre-installed crane base, counterweights and core-drilling

- Installing in a single work shift

- Requiring only minor surface preparation and no structural alterations to the wall or existing components

- Relocating quickly as a single unit

Patent-Pending Design

- Compact design requires wall length of less than 10 feet

- The frame extends vertically less than 4 feet from the top of the wall

- Independent downriggers accommodate variances in the wall thickness

- Custom modifications can be made to meet a nuclear plant's specific needs

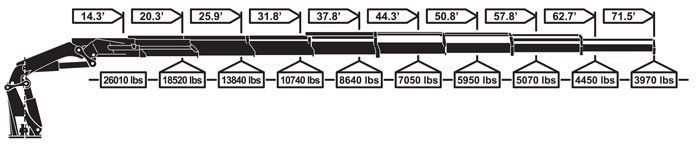

Powerful Capacity

The Scorpion System can be custom-configured to meet a broad spectrum of loading, lifting and handling tasks.

- Maximum Overturning Moment of the crane with an FOS ≈2

- Maximum Moment: 4,000 pounds at 71 feet

- Maximum Winch Capacity: ~8,000 pounds (single-part line), ~16,000 pounds (two-part line)

Horizontal Load Capacity

Safe, Seamless Operation

Wireless controls provide the operator with increased mobility to safely control load handling. Its safety features include:

- 360-degree load handling capacity

- An automated synchronous control system

- Detached hydraulic power unit that provides convenient access to power controls

- Wall clamping force that is continuously monitored by load cells with a digital readout unit